In today’s manufacturing and recycling industries, high-power plastic crushers play a pivotal role in processing plastic waste and preparing raw materials for reuse. Whether you’re operating a recycling plant, plastic molding workshop, or material recovery facility, understanding the inner workings of these machines helps you choose the right equipment and optimize your production flow.

This technical breakdown explores the key components, operating principles, and practical applications of high-power plastic crushers—with insights from Wuxi Songhu Xinrui Machinery Co., Ltd., a trusted manufacturer in the plastics machinery sector. Learn more about the company here: https://www.songhuxr.com/about-us.html.

What Is a High-Power Plastic Crusher?

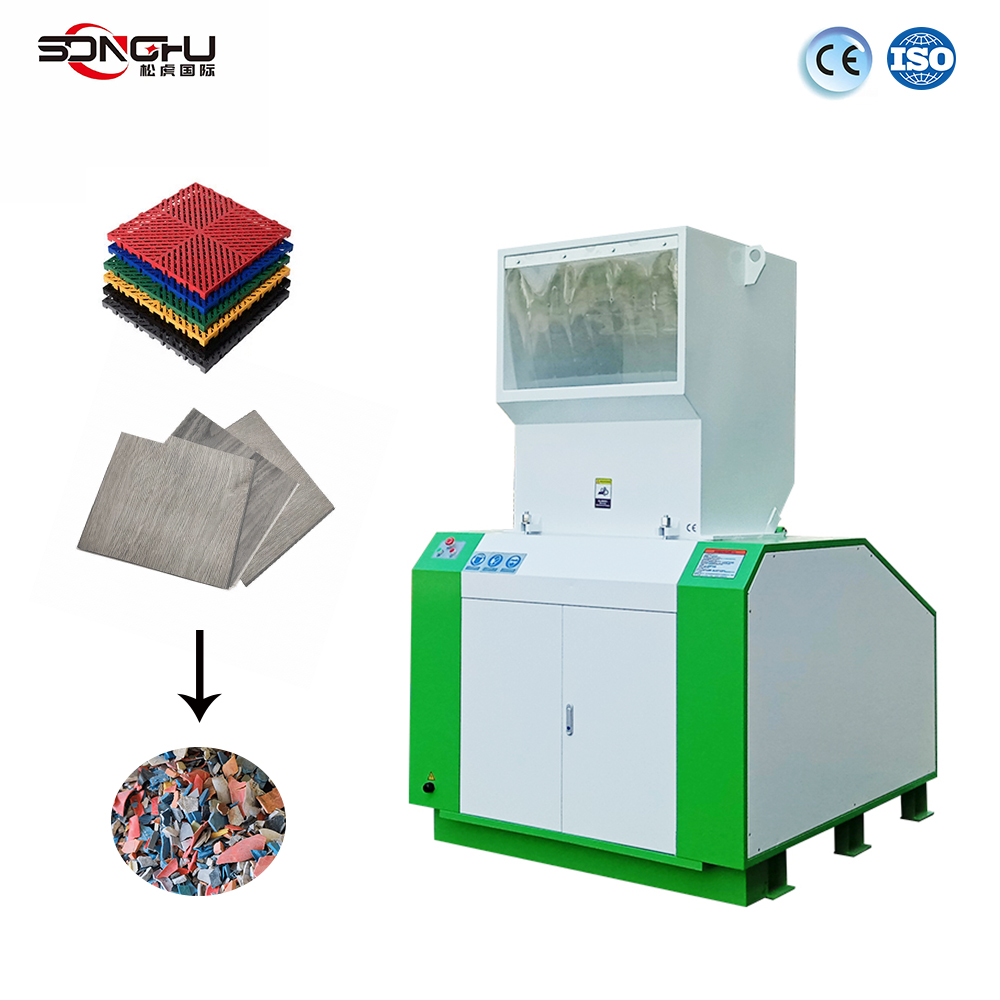

A high-power plastic crusher is a robust industrial machine designed to reduce large, rigid plastic parts into smaller, uniform pieces. These crushed plastics are then suitable for further processing, like extrusion, injection molding, or recycling.

High-power crushers are engineered to handle a variety of plastics—including PE, PP, PVC, ABS, and more—while delivering high throughput and consistent particle size.

Core Components of a High-Power Plastic Crusher

Understanding the anatomy of a plastic crusher helps clarify how it delivers efficient, reliable performance.

1. Crusher Housing & Frame

The outer structure supports all other components and provides rigidity during operation. Heavy-duty steel construction minimizes vibration and noise while ensuring long machine life.

2. Rotor Assembly

The rotor is the heart of the crusher. It consists of a shaft fitted with multiple cutting blades or knives that rotate at high speed. The design of the rotor affects cutting efficiency and material flow.

3. Cutting Blades / Knives

Wear-resistant knives—typically made from hardened alloy steel—slice plastic into smaller pieces. Blades may be fixed or swing-type, depending on the machine design and the types of plastics being processed.

4. Screen or Grate

After initial cutting, plastic pieces fall through a screen with predefined openings. This ensures that only particles of the desired size exit the crushing chamber, while larger pieces remain for further reduction.

5. Feed Hopper

The feed hopper guides plastic waste into the crushing chamber safely and efficiently. Larger hoppers improve productivity by allowing bulk material loading.

6. Drive System

A powerful motor (often 15 kW or higher for high-power models), gearbox, and belt or direct drive transmit torque to the rotor. Drive power directly impacts the crusher’s throughput and capability to handle tough materials.

7. Safety Devices

Safety features such as emergency stop buttons, safety doors, and interlocks protect operators and prevent accidental machine startup during maintenance.

8. Control Panel

Most modern crushers include an electrical control panel for starting/stopping the machine, monitoring motor load, and adjusting operational parameters.

How High-Power Plastic Crushers Work

High-power plastic crushers operate through a sequence of mechanical actions designed to fragment plastic efficiently and safely.

1. Feeding

The plastic material is loaded into the feed hopper, either manually or via automated feeding systems. The hopper’s design ensures a steady flow of material into the crushing chamber.

2. Cutting

Once inside the chamber, the rotating blades on the rotor engage the plastic pieces. High torque from the drive system enables the blades to shear and chip away at rigid plastics, transforming large parts into smaller chunks.

3. Screening

After initial size reduction, the fragmented plastic falls onto a screen or grate. Only pieces small enough to pass through the openings are discharged. Larger pieces remain in the chamber for further cutting.

4. Discharge & Collection

Crushed plastic particles that pass through the screen are collected at the base or transported via conveyor for further processing, such as washing, drying, or pelletizing.

Important Working Principles

Balance of Speed & Torque

High-power crushers rely on the proper balance between rotor speed and motor torque. Too fast a rotor may lead to excessive vibration, while inadequate torque can cause jamming. Manufacturers like Wuxi Songhu Xinrui Machinery Co., Ltd. optimize this balance for consistent performance across various materials: https://www.songhuxr.com/about-us.html.

Knife Design & Configuration

Blade geometry, spacing, and material hardness influence cutting effectiveness and service life. Some crushers use fixed blades for precise cuts, whereas others use swing blades to handle irregular or bulky material without excessive force.

Screen Size Determines Output

The size of screen openings directly controls the final particle size. Custom screens allow operators to tailor output for specific downstream processes like extrusion or injection molding.

Safety First

Advanced interlock systems ensure the crusher cannot operate while doors are open, and overload protection protects the motor from excessive strain.

Applications of High-Power Plastic Crushers

High-power plastic crushers are essential across a wide range of industries:

-

Plastic recycling plants – Reduce waste into reusable granules.

-

Injection molding & extrusion – Prepare scrap and runner parts for reprocessing.

-

Film & sheet processing – Reclaim edge trim and defective products.

-

Automotive & appliance manufacturing – Process bulky plastic housings and components.

Advantages of High-Power Models

-

High throughput and productivity

-

Stable, consistent particle size

-

Reduced manual intervention and labor costs

-

Enhanced safety features

-

Long service life with wear-resistant components

About Wuxi Songhu Xinrui Machinery Co., Ltd.

Wuxi Songhu Xinrui Machinery Co., Ltd. specializes in the design and manufacture of plastic recycling and processing equipment, providing high-quality solutions tailored to diverse industry needs. With a strong commitment to innovation and customer service, Songhu Xinrui delivers reliable machines that improve efficiency, safety, and material utilization. Explore more about the company and its offerings here:

+ There are no comments

Add yours