In heavy industries such as steelmaking, foundry operations, and non-ferrous metal production, managing molten by-products safely and efficiently is essential. One of the most critical components used for this task is the slag pot—a large, durable vessel designed to collect, transport, and dump molten slag generated during metal smelting processes.

This article explores what a slag pot is, how it functions, how it is manufactured, and why choosing a reliable manufacturer like China Special Metal Group Limited (CSM) is crucial for ensuring safety, durability, and performance in metallurgical operations.

1. What Is a Slag Pot?

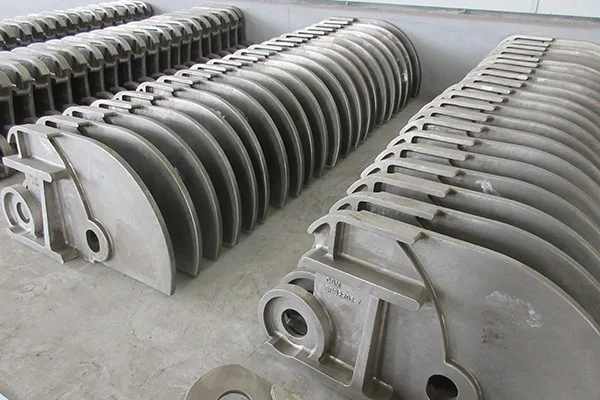

A slag pot, also known as a slag ladle or slag tank, is a large cast steel container used to hold molten slag—the waste material separated from metal during the smelting or refining process. Slag typically consists of metal oxides, silicates, and other impurities that float to the top of molten metal.

The slag pot serves multiple purposes:

-

Collecting molten slag from furnaces or converters.

-

Transporting the hot slag safely to disposal or recycling sites.

-

Dumping and cooling the slag for reuse or further processing.

Due to the extreme temperatures involved—often exceeding 1600°C (2900°F)—slag pots must be made from high-quality, heat-resistant cast steel with exceptional structural integrity.

2. The Role of Slag Pots in Industrial Operations

Slag pots are indispensable in the metallurgical and foundry industries, ensuring the safe handling of molten by-products and supporting continuous production. Their importance includes:

-

Safety: Properly designed slag pots prevent molten slag spillage and reduce the risk of workplace accidents.

-

Efficiency: They streamline slag removal from furnaces, helping maintain uninterrupted smelting operations.

-

Recycling: Many slag types can be cooled and reused in construction materials or cement production, making slag pots part of a sustainable production chain.

China Special Metal Group Limited (CSM) supplies slag pots and other cast steel components that meet the demanding standards of metallurgy, mining, cement, chemical, and shipbuilding industries, ensuring both performance and reliability under extreme conditions.

3. Key Design and Structural Features

A well-designed slag pot must combine strength, durability, and heat resistance. Typical design elements include:

-

Robust wall thickness to withstand mechanical stress and thermal shock.

-

Trunnions or lifting lugs for secure handling by cranes or ladle cars.

-

Reinforced bottom and rim sections to prevent deformation during repeated heating and cooling cycles.

-

Precision-balanced geometry for stable transportation and easy tipping during slag discharge.

CSM uses advanced casting and machining technologies to ensure uniform wall thickness, optimized weight distribution, and superior surface finish—qualities that extend the service life of each slag pot.

4. The Manufacturing Process of a Slag Pot

Producing a slag pot requires strict quality control at every step to ensure it can handle extreme heat and mechanical loads. The general process includes:

Step 1: Design and Simulation

Engineers use 3D modeling and simulation tools to design the slag pot according to specific furnace types, capacities, and operating conditions. This ensures optimal shape, balance, and strength.

Step 2: Mold Preparation

A sand mold or resin mold is prepared based on the final design. The mold must accurately capture every detail to ensure dimensional precision.

Step 3: Casting

Molten steel—formulated with alloy elements for improved heat resistance—is poured into the mold. The casting is left to cool gradually to prevent internal stresses or cracks.

Step 4: Heat Treatment

After solidification, the slag pot undergoes heat treatment (typically annealing or normalizing) to enhance its mechanical properties and relieve casting stresses.

Step 5: Machining and Finishing

CSM applies high-precision machining and surface finishing to ensure accurate dimensions, proper balance, and smooth fitting with handling equipment.

Step 6: Quality Inspection

Every slag pot is subjected to non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection to detect any internal or surface defects before delivery.

5. Why Choose China Special Metal Group Limited (CSM)

With years of expertise in heavy industrial casting, China Special Metal Group Limited (CSM) has become a leading supplier of high-quality cast steel components for metallurgical machinery, cement and mining equipment, shipbuilding, and chemical industries.

Here’s why CSM stands out:

-

Advanced Casting Facilities: Equipped with large-scale foundries capable of producing slag pots up to several tons in weight.

-

Comprehensive Quality Control: Rigorous testing ensures structural integrity and long service life.

-

Customized Design: Each slag pot is engineered to meet the client’s operational requirements and equipment specifications.

-

High-Precision Machining: Ensures perfect fit and stability during high-temperature operations.

-

Global Client Base: Trusted by leading steel mills and foundries across Asia, Europe, and other regions.

CSM’s commitment to innovation, precision, and reliability ensures that every slag pot performs flawlessly under the most demanding industrial conditions.

6. Maintenance and Lifespan

Although slag pots are built to last, regular inspection and maintenance are vital for safety and longevity. Recommended practices include:

-

Checking for cracks, deformation, or wear before each use.

-

Performing periodic non-destructive testing (NDT).

-

Avoiding excessive impact or sudden cooling, which can cause thermal shock.

-

Scheduling routine repairs and refurbishment as needed.

With proper care, a high-quality slag pot from CSM can serve reliably for years of continuous operation, even under harsh environments.

Conclusion

The slag pot is a cornerstone of modern metal smelting operations—essential for handling high-temperature by-products safely and efficiently. Its design, material quality, and manufacturing precision directly influence operational safety and productivity.

By choosing a trusted partner like China Special Metal Group Limited (CSM), businesses gain access to expertly engineered cast steel slag pots and other heavy-duty components designed for maximum performance and durability. With CSM’s combination of advanced technology, strict quality assurance, and customized service, your operations can achieve higher efficiency, safety, and sustainability in every stage of production.

www.special-metal.com

China Special Metal Group Limited (CSM)

+ There are no comments

Add yours