In industries where reliability, precision, and chemical resistance are critical, the tantalum heater stands out as a premium solution. Unlike conventional heating elements, tantalum-based heaters are engineered to perform under aggressive environments such as strong acids, high-purity processes, and extreme thermal conditions. The unique properties of tantalum—high melting point, outstanding corrosion resistance, and chemical inertness—make the tantalum heater a preferred choice in chemical processing, semiconductor manufacturing, and laboratory research. As industries require increasingly safe and stable heating systems, the tantalum heater has become an indispensable tool for controlled and efficient thermal management.

Material Advantages of Tantalum in Heating Systems

The superior performance of a tantalum heater is directly linked to the characteristics of the metal itself:

-

Exceptional Corrosion Resistance: Tantalum resists most acids, including hydrochloric, nitric, and sulfuric acids, even at elevated temperatures.

-

High Melting Point: With a melting point of approximately 3017°C, tantalum can endure extreme heat without structural failure.

-

Excellent Thermal Conductivity: This property ensures efficient and uniform heat transfer, reducing hotspots.

-

Non-reactivity: Tantalum is biocompatible and chemically stable, making it suitable for processes requiring high purity.

-

Mechanical Strength: Despite being ductile, tantalum maintains mechanical stability in harsh operational environments.

These qualities explain why a tantalum heater excels where other metallic heaters degrade or corrode quickly.

Design Configurations of Tantalum Heaters

The performance of a tantalum heater is influenced not only by the quality of the material but also by the design of the heating element. Manufacturers provide various configurations tailored to meet specific industrial needs, ensuring that each type of tantalum heater performs optimally in its intended application.

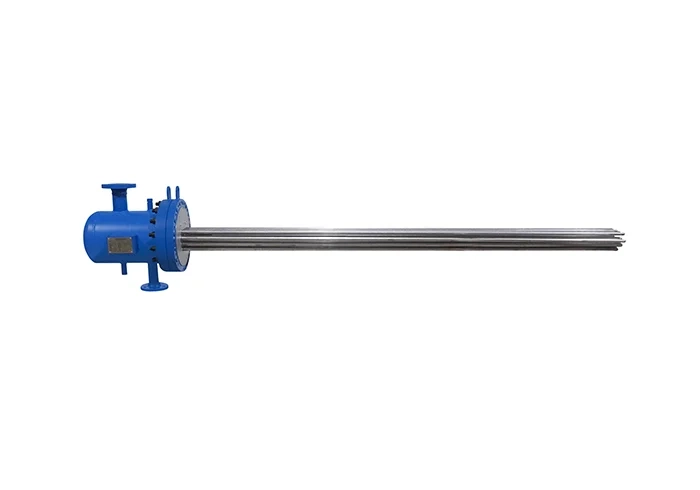

1. Immersion Tantalum Heaters

Immersion tantalum heaters are designed for direct heating of corrosive liquids. These heaters are typically constructed using tantalum tubing or sheathing to withstand extreme temperatures and corrosive environments. Immersion heaters are ideal for applications in chemical processing tanks, plating baths, and acid heating systems, where traditional heating elements would fail due to aggressive chemical exposure. The use of tantalum ensures a long-lasting and highly reliable performance in these harsh conditions, making it an essential solution for industries requiring consistent heat transfer and minimal wear.

2. Tantalum Cartridge Heaters

Compact and efficient, tantalum cartridge heaters are designed to fit into drilled holes or housings, providing precise, localized heating. Their small form factor makes them ideal for applications where space is limited. The tantalum heater casing ensures durability and resistance to corrosion, even in aggressive chemical environments or high-purity applications where contamination is a concern. These heaters are commonly used in industrial processes requiring high heat output in a small, concentrated area, such as in reactors, extrusion systems, and other specialized equipment.

3. Tantalum Strip or Foil Heaters

Tantalum strip heaters are designed for laboratory and semiconductor applications where quick and uniform heating is crucial. With their thin, flexible profiles, tantalum foil heaters offer versatility, making them suitable for various laboratory experiments and precision applications. Their flexibility allows them to conform to different shapes and sizes, providing an even heat distribution. The inert surface of tantalum ensures that these heaters can be used in environments requiring high purity, such as in the semiconductor industry, where contamination can affect the integrity of the materials being processed.

4. Tantalum Rod Heaters

Robust and durable, tantalum rod heaters are ideal for large-scale industrial applications requiring long-term durability and consistent performance. These heaters are especially effective in environments exposed to corrosive atmospheres, offering reliability over extended periods of operation. Tantalum rod heaters are used in applications such as high-temperature furnaces, vacuum chambers, and other systems where prolonged exposure to aggressive chemicals or extreme heat is common. Their strength and resilience make them a critical component for large-scale processes that demand continuous, efficient heating.

Each of these tantalum heater configurations provides unique advantages, offering tailored solutions for industries that require chemical resistance, high heat transfer efficiency, and durability.

Applications of Tantalum Heaters Across Industries

The tantalum heater has become an essential solution in various industries that demand both chemical resistance and precise thermal control. Its exceptional ability to maintain stable performance in aggressive environments makes it invaluable in many sectors.

Chemical Processing

In processes that involve aggressive acids like hydrochloric or sulfuric acid, traditional heating elements often fail due to corrosion. Tantalum heaters, however, are able to withstand these harsh environments, providing consistent thermal output over long periods. Their resistance to chemical attack ensures that the heating element remains stable throughout the process, allowing for reliable operation in acid-based chemical reactions such as distillation and treatment.

Semiconductor Manufacturing

The semiconductor industry requires high-purity materials to ensure the integrity of sensitive processes such as wafer cleaning, etching, and deposition. The inert surface of a tantalum heater makes it ideal for these applications, as it prevents contamination during heating. Tantalum heaters are used in semiconductor fabrication to maintain the temperature stability necessary for precise material deposition, ensuring the quality and purity of semiconductor components.

Pharmaceutical and Biotechnology

In the pharmaceutical and biotechnology industries, the production of drugs and medical products must take place in sterile environments. Tantalum heaters are capable of resisting cleaning chemicals and maintaining biocompatibility, making them an excellent choice for use in controlled environments such as cleanrooms and bioreactors. Their ability to endure exposure to a variety of chemical agents while maintaining precise heating control makes them essential in processes like sterile manufacturing and laboratory research.

Aerospace and Defense

The aerospace and defense industries require materials and components that can withstand extreme conditions. Tantalum heaters are used in the heat treatment of aerospace components that must maintain stability even in vacuum or chemically aggressive environments. These heaters provide controlled, reliable heating during the manufacturing of critical components, such as engine parts and structural elements, ensuring their performance and durability in high-stress conditions.

Laboratory Research

In laboratory research, precise and reliable heating is crucial for the accuracy of experimental results. Tantalum heaters are commonly used in high-temperature reactions and for heating corrosive liquids in laboratory setups. Their resistance to corrosion and their ability to provide uniform heating make them indispensable for experiments requiring stability and reproducibility. Whether used in small-scale lab applications or larger-scale industrial research, tantalum heaters offer the performance required for reliable results.

In conclusion, tantalum heaters offer unparalleled performance and reliability across a wide range of demanding applications. Their exceptional corrosion resistance, high melting point, and thermal efficiency make them the ideal choice for industries such as chemical processing, semiconductor manufacturing, pharmaceuticals, aerospace, and laboratory research. With various design configurations tailored to meet the unique needs of each industry, tantalum heaters provide efficient, stable, and long-lasting thermal management solutions. As industries continue to push the boundaries of technology and process requirements, the tantalum heater will remain a critical tool for achieving precise, safe, and sustainable thermal control in even the most aggressive environments.

https://www.tnztn.com/Tantalum-Bayonet-Heater

www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd.

+ There are no comments

Add yours