OEM rotomold molds play a vital role in the production of durable, hollow plastic products across a wide range of industries. Rotational molding is valued for its ability to create complex shapes with uniform wall thickness, excellent structural strength, and minimal internal stress. As demand for customized plastic products continues to grow, OEM rotomold molds have become essential tools for manufacturers seeking flexibility, quality, and cost efficiency.

Industrial Tanks and Containers

One of the most common applications of OEM rotomold molds is in the production of industrial tanks and containers. These products are widely used for water storage, chemical handling, agriculture, and industrial processing. Rotomolding allows tanks to be produced without seams or welds, reducing the risk of leakage and improving long-term durability. Custom molds enable manufacturers to design tanks with specific capacities, wall thicknesses, and integrated features such as fittings, ribs, and reinforced areas.

Outdoor Furniture and Leisure Equipment

Outdoor furniture and leisure products demand strong weather resistance, impact strength, and attractive design. OEM rotomold molds make it possible to manufacture chairs, tables, storage boxes, playground equipment, and other outdoor items with smooth surfaces and consistent quality. The process supports UV-stabilized materials and textured mold finishes, helping products withstand long-term exposure to sunlight and harsh environments while maintaining visual appeal.

Kayaks, Canoes, and Water Sports Products

Water sports products are another key application area for OEM rotomold molds. Kayaks, canoes, and related equipment require lightweight construction combined with high impact resistance and buoyancy. Rotational molding allows manufacturers to create one-piece, hollow structures that offer excellent strength and balance. Custom mold design also enables ergonomic shapes, reinforced hulls, and integrated seating or storage features tailored to different performance needs.

Automotive Parts and Components

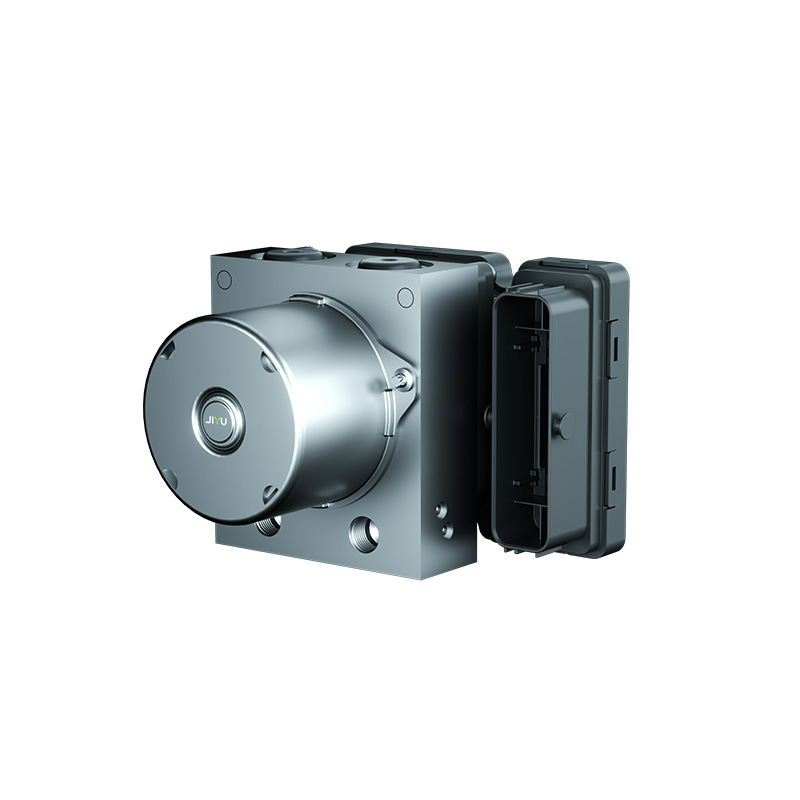

In the automotive industry, OEM rotomold molds are used to produce a variety of plastic components, including air ducts, fluid reservoirs, toolboxes, and protective covers. Rotomolded automotive parts benefit from uniform wall thickness, chemical resistance, and the ability to integrate complex geometries without additional assembly. Custom molds ensure that components meet specific performance and fitment requirements.

Custom Rotational Molding Products

Beyond standard applications, OEM rotomold molds are widely used for fully customized products designed for specialized industries. From medical equipment housings to industrial enclosures and unique consumer products, rotational molding offers designers the freedom to innovate. OEM molds are developed to match precise specifications, enabling efficient production of unique shapes and functional features that are difficult to achieve with other molding methods.

Comprehensive Mold Manufacturing Expertise

XINGHUI MOLD is one of China’s professional rotomold mold manufacturers, specializing in the design and production of rotomold molds, vacuum forming molds, blow molds, foam molds, and rotomolded products. With experience serving diverse industries such as outdoor furniture and leisure equipment, water sports products, industrial tanks and containers, automotive parts, and custom-designed rotational molding products, the company offers comprehensive solutions from design to manufacturing.

Supporting Quality and Long-Term Performance

High-quality OEM rotomold molds are essential for ensuring consistent product performance and production efficiency. Precision machining, appropriate mold materials, and well-designed structures contribute to longer mold life and stable output. Manufacturers with broad technical expertise can help optimize mold design to reduce cycle times, improve surface quality, and lower overall production costs.

Conclusion

OEM rotomold mold applications span a wide range of industries, from heavy-duty industrial tanks to lightweight outdoor and leisure products. Their versatility, durability, and design flexibility make them a preferred choice for custom plastic manufacturing. By working with experienced mold manufacturers like XINGHUI MOLD, businesses can develop reliable, high-performance rotational molding solutions that meet diverse application requirements and support long-term growth.

www.xinghuimould.com

Ningbo Xinghui Rotational Molding Technology Co., Ltd.

+ There are no comments

Add yours