Introduction: Safety Risks in Material Handling Systems

In industries such as cement, metallurgy, ports, mines, and energy, the handling of bulk materials presents numerous safety challenges. Operators face risks from material spills, equipment malfunctions, and uncontrolled flow, which can lead to injuries, production downtime, and environmental hazards. Ensuring the safe operation of material handling systems is critical not only for compliance with regulations but also for protecting workers and maintaining operational efficiency.

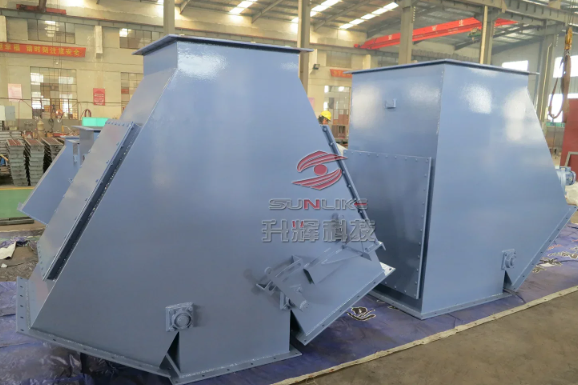

High-quality four-way dispensing valves play a vital role in mitigating these risks by providing precise control over material flow, reducing human error, and supporting automated systems that enhance overall safety.

Valve Features That Enhance Operational Safety

Modern four-way dispensing valves are engineered to improve operational safety through several key features:

-

Precision Flow Control: By accurately directing bulk materials, these valves prevent accidental overflows and reduce the risk of spillage.

-

Durable Construction: High-quality materials and reinforced designs minimize the likelihood of valve failure under heavy loads or harsh industrial conditions.

-

Automation Integration: Compatible with electrical automation control systems, these valves can be remotely monitored and controlled, reducing the need for manual intervention in potentially hazardous environments.

-

Emergency Shutoff Capabilities: Advanced designs allow for quick shutoff during malfunctions, preventing accidents and equipment damage.

Maintenance Practices and Monitoring Systems

Even the best-designed valves require regular maintenance and monitoring to ensure optimal safety:

-

Routine Inspections: Checking for wear, corrosion, and proper alignment of valve components.

-

Lubrication and Cleaning: Maintaining moving parts to prevent jams and ensure smooth operation.

-

Monitoring Systems: Integration with flue gas ring exhaust, grinding, homogenization, and transport control systems allows operators to track valve performance in real time.

-

Scheduled Replacements: Components subject to heavy wear should be replaced proactively to prevent unexpected failures.

These practices ensure that four-way dispensing valves continue to provide reliable and safe operation over the long term.

Sunlike Machinery’s High-Quality Components and Engineering Standards

Sunlike Machinery has established itself as a leading manufacturer and engineering service provider for bulk material handling systems. With certifications in environmental pollution control engineering, production qualifications, and professional contracting, the company delivers:

-

Precision-engineered four-way dispensing valves tailored for heavy industries.

-

Complete equipment solutions for grinding, dust removal, homogenization, transportation, storage, loading, and unloading of bulk materials.

-

Custom manufacturing and special specifications to meet unique operational requirements.

-

Integration with electrical automation and monitoring systems, enhancing safety and efficiency across production lines.

By adhering to strict engineering standards and using high-quality components, Sunlike Machinery ensures that its valves minimize risks, improve process control, and support safer industrial operations.

Conclusion: Reliable Valves Reduce Accidents and Improve System Safety

The safe handling of bulk materials is critical for protecting workers, equipment, and the environment. High-quality four-way dispensing valves, combined with proper maintenance and monitoring, are essential tools for mitigating safety risks.

With Sunlike Machinery’s expertise, durable components, and integrated engineering solutions, industries can achieve reliable, efficient, and safe material handling systems. Investing in quality valves not only safeguards personnel but also enhances overall operational efficiency and productivity.

www.cn-sunlike.com

Nantong Sunlike Machinery Co., Ltd.

+ There are no comments

Add yours