In the world of modern construction and industrial design, choosing the right aluminum profile can significantly impact energy efficiency, performance, and long-term value. One of the most common questions engineers and project planners ask is: What’s the difference between heat insulating and non-insulating aluminum profiles? In this article, we’ll break down the key differences, benefits, and considerations when selecting between the two—especially when sourcing from advanced manufacturers like Kai Mei Da.

1. What Are Heat Insulating Aluminum Profiles?

Heat insulating aluminum profiles are engineered with thermal break technology. This means a layer of insulation material—often made of polyamide or other low-conductivity polymers—is placed between the interior and exterior sections of the profile. This layer interrupts the flow of heat, reducing thermal transfer between indoors and outdoors.

These profiles are ideal for windows, doors, and curtain walls in climates where temperature control is crucial. By minimizing heat loss or gain, they contribute to reduced HVAC costs and improved indoor comfort.

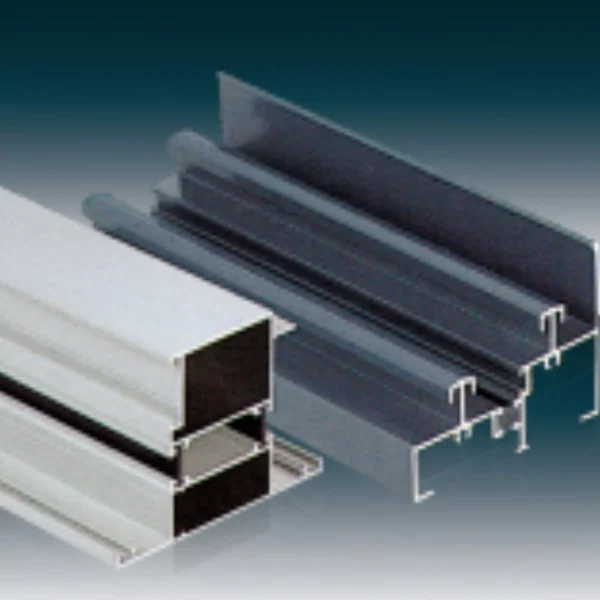

2. What About Non-Insulating Aluminum Profiles?

Non-insulating aluminum profiles, on the other hand, are made from a single continuous piece of aluminum. They do not have any thermal break, which means heat or cold can easily pass through the material. While this might be acceptable for interior applications or environments where insulation is not a concern, it can lead to significant energy inefficiency in exterior-facing structures.

These profiles are typically more affordable and are still widely used in applications where thermal performance is not a primary consideration.

3. Key Material and Performance Differences

The main functional difference lies in thermal conductivity. Heat insulating aluminum profiles can reduce U-values (a measure of heat transfer) significantly—down to ≤2.7W/M²·K when combined with suitable glass. In contrast, non-insulating profiles have much higher U-values, allowing more heat exchange.

Additionally, the longitudinal anti-shearing value of high-quality insulating profiles reaches ≥24N/mm, enhancing durability and structural stability.

4. Application Scenarios: When to Choose Each

Choosing between the two types depends on the application:

-

Heat insulating aluminum profiles are ideal for:

-

Residential and commercial buildings in cold or hot climates

-

Energy-saving construction projects

-

High-performance curtain walls and thermal windows

-

Green building certifications (e.g., LEED)

-

Non-insulating profiles work well for:

-

Interior partitions

-

Industrial equipment housings

-

Temporary structures

-

Projects with minimal thermal control requirements

5. How Manufacturing Impacts Performance

Our company, certified by ISO9001 and ISO14001 systems, utilizes advanced production techniques including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain finishes. We also adopt Japanese and German inspection devices, ensuring strict adherence to national standards (GB/T 5237.1~6—2017 and GB5237.4-2008).

These manufacturing processes are essential in enhancing the surface durability, corrosion resistance, and appearance of both types of aluminum profiles. But for heat insulating profiles in particular, the precision of the thermal break integration is critical for performance.

6. Cost vs. Value Considerations

While heat insulating aluminum profiles are typically more expensive upfront due to their complex structure and materials, they offer long-term value through energy savings, durability, and better insulation performance. Non-insulating profiles may save money initially, but could result in higher utility bills and lower building comfort over time.

When working with trusted suppliers like those under the Kai Mei Da brands, buyers can count on high technology, complete specifications, and customizable production according to design drawings.

7. Environmental Impact

Heat insulating aluminum profiles support sustainable building goals by reducing energy consumption. Combined with eco-friendly production systems, such as our 5S field management and quality control departments, these profiles contribute to both environmental responsibility and long-term efficiency.

8. Final Thoughts: Choose Based on Performance Needs

In conclusion, the difference between heat insulating and non-insulating aluminum profiles lies in their thermal behavior, structural complexity, and energy performance. If your project demands durability, thermal control, and environmental compliance, heat insulating aluminum profiles are the right choice. For interior or low-demand environments, non-insulating options may suffice.

Either way, partnering with a manufacturer that prioritizes quality, customization, and innovation—like our team—ensures you get the most suitable aluminum profiles for your application.

www.jxkmdly.com

Jiangxi KaiMeiDa aluminum

+ There are no comments

Add yours