In the fast-paced world of pharmaceutical manufacturing, achieving high efficiency, precision, and safety in injectable drug production is paramount. Jiangsu Pharmasys Intelligent Equipment Co., Ltd., a leading supplier of aseptic pharmaceutical equipment, offers semi-automatic capping machines that are designed to streamline production processes, reduce downtime, and ensure compliance with stringent quality standards.

Why Semi-Automatic Capping Machines Are Critical

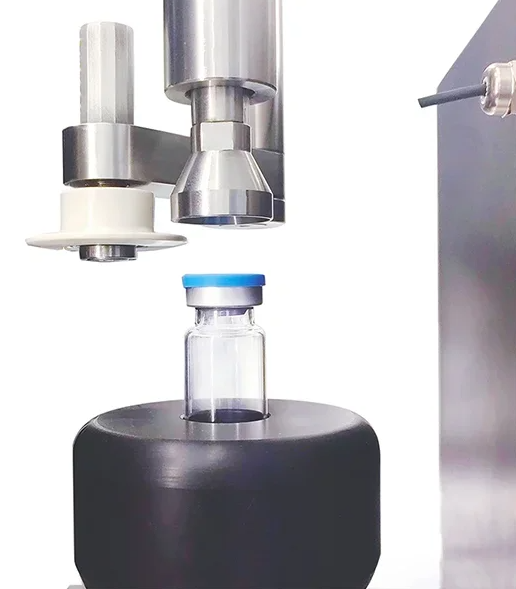

Capping is a crucial step in aseptic filling lines, as it ensures the sterility, integrity, and stability of injectable drugs. Choosing the right semi-automatic capping machine can dramatically improve production efficiency while minimizing human error and the risk of cross-contamination.

Pharmasys Intelligent’s semi-automatic capping machines are engineered with features that directly address the challenges of commercial production:

-

Rapid Process Scaling: Designed based on commercial production experience, our machines enable fast scale-up of operations without compromising quality.

-

Compatibility with Multiple Filling Methods: Works seamlessly with piston pumps, peristaltic pumps, and gel filling systems.

-

Reduced Foaming and Cross-Contamination Risk: Follow-up filling methods control foaming and minimize contamination risks.

-

Flexible Operation and Production Setup: Easy-to-adjust production parameters to match specific manufacturing needs.

-

Quick Toolless Part Replacement: Components can be changed rapidly without tools, minimizing downtime.

-

Recipe Management and Authority Control: Supports recipe management with three-level authority, and key parameters are visualized for operational transparency.

-

Integration with SMART-21 Stoppering Machine: Can be combined with Pharmasys SMART-21 series semi-automatic stoppering machines for a complete aseptic line.

-

Customizable Design: Machines can be tailored to suit specific customer workflows and operating habits.

Applications in Pharmaceutical Production

Our semi-automatic capping machines are widely applied in:

-

Biopharmaceuticals: Ensuring precise capping for vials, prefilled syringes, and advanced formulations.

-

Medical Aesthetics: Efficient production of injectable aesthetic products.

-

Advanced Formulation Sectors: Supporting small- to medium-scale production lines requiring high sterility and flexibility.

These machines are ideal for manufacturers who need high-performance, cost-effective solutions without compromising production speed or quality.

Key Advantages

-

Enhanced Efficiency: Rapid process scaling and flexible production setups reduce cycle time and increase output.

-

Operational Safety: Risk of foaming, spillage, and cross-contamination is minimized.

-

Ease of Maintenance: Toolless part replacement and modular design reduce downtime and operational complexity.

-

Customizable Workflow: Machines adapt to unique operating habits, improving user experience and productivity.

-

Integrated Aseptic Solution: Works in conjunction with other Pharmasys equipment for a fully aseptic production line.

Conclusion

Investing in a Pharmasys Intelligent semi-automatic capping machine ensures that your injectable drug production line is efficient, safe, and adaptable. With rapid scaling, flexible operation, and integration capabilities, these machines are tailored to meet the demands of modern pharmaceutical manufacturing.

For biopharmaceutical, medical aesthetic, and advanced formulation manufacturers seeking precision, reliability, and cost-effective performance, Pharmasys Intelligent offers a solution that maximizes production efficiency while maintaining the highest quality standards.

www.sino-pharmasys.com

Jiangsu Pharmasys Intelligent Equipment Co., Ltd.

+ There are no comments

Add yours