In modern engineering and industrial applications, gears remain one of the most vital components for power transmission, motion control, and efficiency. Choosing a high precision custom gear manufacturer is crucial for businesses that rely on accuracy, durability, and performance. Unlike standard off-the-shelf gears, custom-designed gears allow companies to meet specific requirements in sectors such as automotive, robotics, energy, and medical equipment. Longruifa will share the role of high precision custom gear manufacturer and its importance in industrial gear production, which is indispensable in the industry.

The Role of High Precision Custom Gear Manufacturer

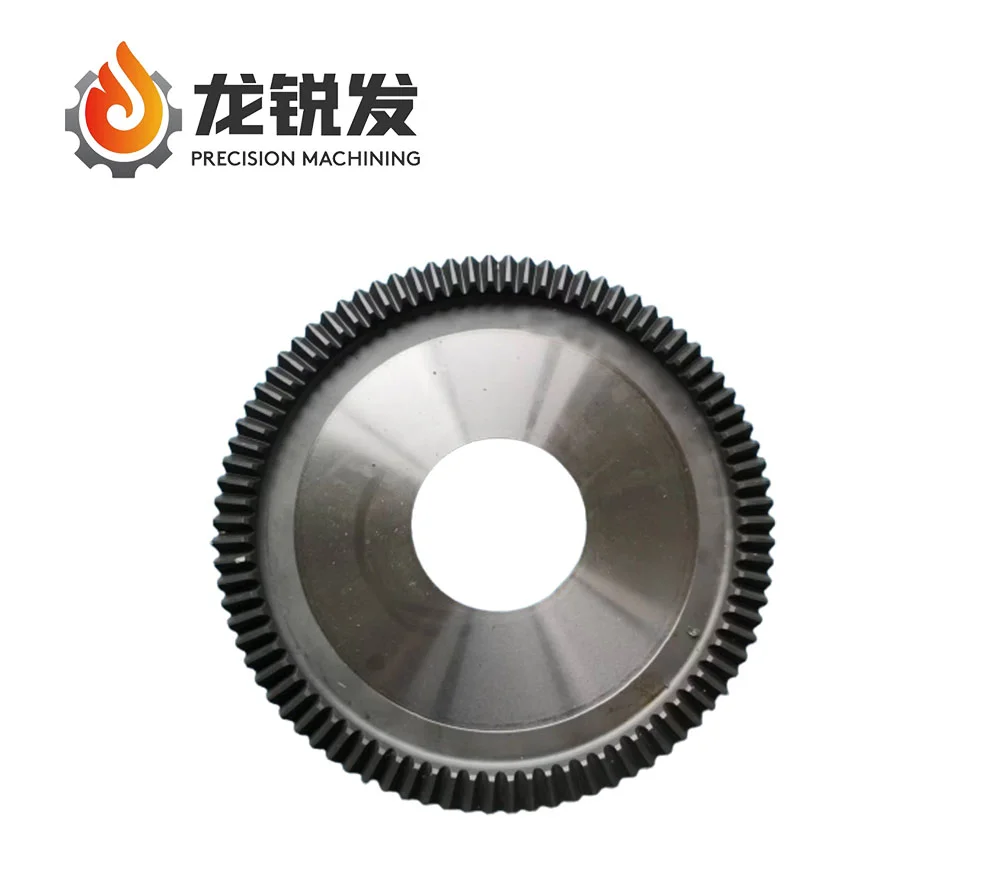

A custom gear manufacturer goes beyond simple gear production. Their role involves advanced engineering expertise, modern CNC machining, rigorous quality testing, and precision assembly. These manufacturers provide tailor-made solutions that optimize efficiency, minimize noise, and extend the lifespan of machinery. By focusing on precision, they reduce mechanical failures and ensure smoother performance across complex systems.

Advanced Technologies in Industrial Gear Production

Modern high precision gear manufacturers integrate cutting-edge technologies to meet strict tolerance and performance standards. Some of the most notable include:

-

CNC Gear Hobbing and Shaping – Enables precise cutting of gear teeth for maximum accuracy.

-

5-Axis Machining – Facilitates complex geometries and custom profiles for specialized industries.

-

Heat Treatment and Surface Finishing – Enhances durability, wear resistance, and load-bearing capacity.

-

3D Metrology and Inspection Systems – Guarantees compliance with international gear standards such as AGMA and ISO.

These processes ensure that each gear, whether spur, helical, bevel, or worm, meets the stringent requirements of advanced mechanical systems.

Why Industries Rely on Precision Custom Gear Manufacturers

From heavy-duty construction machinery to lightweight aerospace equipment, industries demand gears that perform flawlessly under varied conditions. A custom gear manufacturer provides:

-

Tailored Solutions – Every gear design is optimized for load, speed, torque, and application-specific demands.

-

Consistency and Accuracy – Precision gears reduce vibration, noise, and energy loss.

-

Extended Equipment Life – High-quality gears minimize wear and tear, lowering maintenance costs.

-

Global Competitiveness – Precision engineering enhances product quality, giving companies an edge in international markets.

High Precision Gear Manufacturing for Specialized Applications

Different sectors require unique gear characteristics. A reliable custom gear manufacturer adapts production methods to suit these industries:

-

Automotive and Electric Vehicles (EVs) – High-efficiency gears improve energy transfer in drivetrains.

-

Aerospace and Defense – Lightweight, durable gears ensure reliability in critical missions.

-

Medical Devices – Miniature precision gears power surgical robots and diagnostic machines.

-

Industrial Robotics – Custom gears enhance motion accuracy, repeatability, and productivity.

-

Renewable Energy – Gears in wind turbines and solar trackers demand strength and precision for continuous operation.

Comparing Standard vs. Precision Custom Gear

Businesses often debate whether to use standard gears or invest in high precision custom gear manufacturing. While standard gears may be cost-effective initially, they often lack the durability and efficiency required for specialized equipment. In contrast, precision gears deliver:

-

Optimized Design Fit – Perfect alignment with system requirements.

-

Lower Operational Costs – Reduced downtime and longer service intervals.

-

Improved Safety and Reliability – Especially critical in aerospace, medical, and defense sectors.

Investing in precision gears ensures long-term performance gains that outweigh upfront costs.

Choosing the Right Custom Gear Manufacturer

Selecting a partner for custom gear manufacturing requires careful evaluation. Key factors include:

-

Engineering Expertise – The manufacturer should have strong R&D capabilities.

-

Quality Certifications – Look for ISO 9001, IATF 16949, or AS9100 compliance.

-

Manufacturing Capabilities – Ability to handle diverse materials such as steel, brass, titanium, and composites.

-

Customization Flexibility – Offering solutions for both low-volume prototyping and high-volume production.

-

Global Supply Chain Support – Timely delivery and after-sales service to meet international project needs.

Innovations Shaping the Future of Custom Gear Manufacturing

The future of high precision gear manufacturing is influenced by smart technologies and sustainability. Some trends include:

-

Additive Manufacturing (3D Printing) for rapid prototyping of gear prototypes.

-

AI-Powered Design Software that simulates gear performance under multiple conditions.

-

Eco-Friendly Manufacturing Processes to reduce energy waste and carbon footprint.

-

Integration with IoT and Smart Factories to monitor gear performance in real-time.

These innovations ensure that gear manufacturers stay ahead of evolving industrial demands.

Conclusion

In an era of advanced engineering and increasing demand for accuracy, partnering with a high precision custom gear manufacturer is essential for industries striving for innovation and reliability. Custom gears are no longer optional; they are the foundation of efficiency, safety, and long-term performance. By choosing an experienced manufacturer with strong technological expertise and a commitment to quality, companies can achieve higher productivity, lower operational risks, and greater competitiveness in global markets.

www.lrfgears.com

Longruifa

+ There are no comments

Add yours